The Model 201 LP Broken bag detector is powered through a 24VDC signal. They are commonly used as a broken bag detector in bag houses and to detect leaks or.

Find Leaking Baghouse Filters Faster With A Triboelectric Broken Bag Detector Baghouse Com

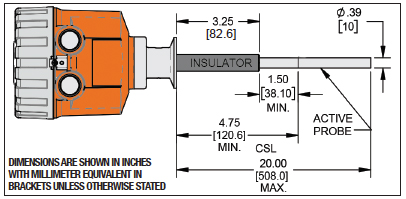

C TECHNICAL SPECIFICATIONS FUNCTIONAL Output Relay DPDT 5A 250 VAC or 28 VDC Input Power 120 or 240 VAC 60 Hz Temperature Range -40 to 180 F -40 to 80 C Probe 325 F 162 C maximum.

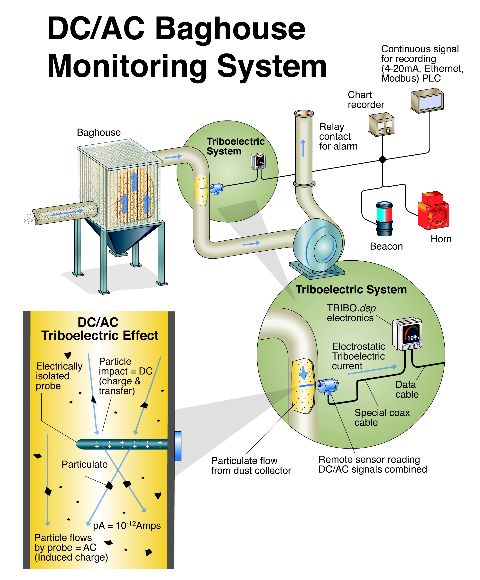

. While theres a good chance you dont keep up-to-date with triboelectric broken bag detector news in recent years technological innovations have completely changed how accurate and reliable these detectors can be. It does not impose regulatory requirements. The guidance addresses only one suggested approach to the use of bag leak detectors.

The 201LP is a cost-effective device for multiple compartment bag house applications. Ideally suited to applications from 01 mgm3 it provides an immediate alarm in case of a filter break. The DustmAlar is suc-cessfully utilized in a wide variety of applications wher e detection of dust levels is critical either to safety mainte-nance equipment operation plant efficiency andor the.

The U3200 is designed to monitor fabric filter baghouses cartridge. The DustmAlar Broken Bag Detector provides reliable and economical detection of leaks and filter failures in many powder and bulk solids industries. Modern broken bag detectors help engineers meet strict compliance and certification requirements with the.

1 Software Tools and Alarm Reporting. This document provides guidance on the use of triboelectric monitors as fabric filter bag leak detectors. Evolving with the times todays broken bag detectors have technical capabilities far beyond past models.

Series CAB Connects Series PMS to Series DPM Sensor Cable that is used with the Series PMS Particulate Sensor. A simple solution to identify failure of a fabric filter baghouse cartridge filters or cyclones. Principle Triboelectric effect Damping time 1 s Output signals 1 Alarm output potential-free NONC Sensor rod Total length.

The remote alarm is by others. Broken Bag Detectors are designed to provide a safe and reliable means of detecting leaks and failures in industries that specialize in handling powder and bulk solids. However proper setup and operation of a bag leak detector can vary with site-specific conditions and those.

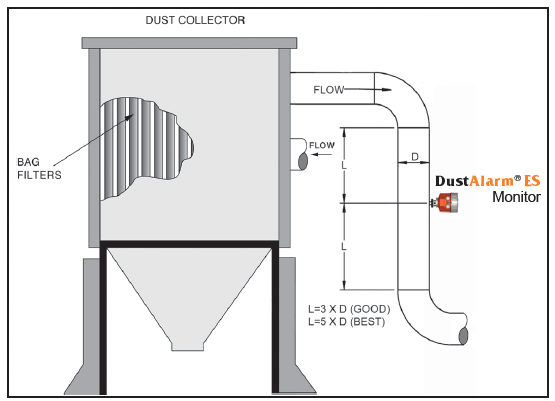

Using an array of monitors on bag house compartments andor outlet ducts is an excellent means of detecting broken bags before an emissions exceedance is reached. Control Panel BBD6-4200 - in a NEMA 4 enclosure which allows for remote adjustment of probe sensitivity alarm set-point and time delay. The bag leak detectors are used in a large variety of applications which require detection of dust particles as part of maintenance or environmental requirements.

Broken Bag Detector Flo-Guard Pneumatic Conveying Flow. It is sensitive enough to not only detect broken bags but also to detect the presence of worn bags. The TRIBOdsp U3200 Integral model is an advanced and economical particulate detector for dust collector compliance maintenance and process applications.

Triboelectric broken bag detectors measure the amount of static electricity generated by dust particles in an airstream. DUSTY is a filter guard working on the principle of triboelectronic technology. Dust detection devices continuously monitor particulate emissions through an air filtration system and alert when levels meet a predetermined threshold thereby detecting levels of particulate matter that exceed regulatory standards and potentially put employee health at risk.

3 GD zone 2 gas zone 22 dust Protection category IP 65 Power supply 24 10 V DC Power consumption 1 W Electrical connection. The user will be immediately informed if there are possibly defects at the dust filter. 3 Shree TECS Pvt.

The bag leak detectors are used in a large variety of applications which require detection of dust particles as part of maintenance or environmental requirements. From Process - Broken Bag Detection. Broken Bag Detectors are designed to provide a safe and reliable means of detecting leaks and failures in industries that specialize in handling powder and bulk solids.

The Dusty has been designed for reliable broken bag detection without delay. Posted by Earl Parker on Mar 10 2016 13000 PM. Sensitivity The Model 201LP system can detect a particulate loading as small as 0005grdscf 1mgm3.

Goyen BBD6-4200 Broken Bag Detection System will detect dust that may bypass a dust collection system and provide a relay output to a central control area where the alarm would be activated. A reference point is set by the sensitivity control adjustment aided by the tri-color LED. In this blog well take a deeper look into six of the most progressive modern innovations for broken bag detectors and detail how they help engineers worldwide in their day-to-day applications.

194 mm Enclosure Aluminium Using in Ex-zones Cat. Particulate Dust or Broken Bag Sensors. Schenck Process offers Integral Broken Bag Dectors from Auburn Systems.

Integral Broken Bag Detector. The alarm point is set by an alarm level control adjustment. Cost effective broken bag detection.

- ˇˆ ˆ - 6. The DustAlarm Broken Bag Detector incorporates visual indications and a relay output to maximize its user-friendliness and automation capabilities. Dust particles generate an electrical current when they encounter the insulated metal probe in the ductwork.

Dusty is usable in all metallic channels in which dust particles should be detected. -ˇˇ ˇ ˆ. 1023 in length of stainless steel rod.

Broken Bag Detector Dust Alarm Es

Manufacturers And Exporters Of Broken Bag Detectors Shree Tecs India

Bag Leak Detectors Or Broken Bag Detectors Used In Bag House Collectors

0 komentar

Posting Komentar